The M8 Grenade Launcher

Date Written: June, 2015

Author: Chris Guska

Background:

At the squad level for the US Army, the primary means of anti vehicle defense was the rifle grenade. Grenade launchers were allocated at minimum one per squad, with two per squad in specific TO&E’s. The M1 launcher on the M1903 Springfield rifle was the primary rifle grenade launching platform until the launchers for the Garand and Carbine could be developed and satisfactorily tested. In the spring of 1943, the M7 grenade launcher for the M1 Garand and M8 grenade launcher for the M1 carbine were standardized and production started.

The M8 grenade launcher for the M1 carbine is not well recognized or understood by reenactors. Common myths amongst reenactors are that the M8 was only used in the PTO, and it wasn't a regularly issued item in the Army. My hope is to firmly put those myths to bed and have reenactors re-examine the M8 grenade launcher and their place in ETO impressions.

TO&E:

In the Infantry Regiment, as of the 1944 Tables of Organization and Equipment, there was one grenade launcher allocated for every six men (3360 Enlisted and Officers / 554 launchers). Of those 554 total launchers in the regiment, 97 were M8 grenade launchers for the M1 carbine, with largest allocation to the heavy weapons companies and the cannon company.The heavy weapons company had the highest concentration of M8's because of their widespread use of the M1 carbine, specifically amongst messengers and ammunition bearers, as detailed below:

Examples of specific roles that utilized the M8 grenade launcher within the heavy weapons company are:

- Reconnaissance Sergeant

- Communications Sergeant

- Bugler

- Messengers (Driver of 1/4 ton truck, Jeep)

- Ammunition Bearers, MG and Mortar, (Drivers of 1/4 ton truck, Jeep)In the cannon company:

- Reconnaissance Sergeant

- Communications Sergeant

- Bugler (Driver of 1/4 ton truck, Jeep)

- Messengers (Driver of 1/4 ton truck, Jeep)In the anti tank company:

- Reconnaissance Sergeant

- Communications Sergeant

- Bugler (Driver of 3/4 ton truck, Weapons Carrier)

- Messengers (Driver of 1/4 ton truck, Jeep)In the regimental headquarters:

- Radio Sergeant

- Bugler (Driver of 1/4 ton truck, Jeep)

- Orderlies (Driver of 1/4 ton truck, Jeep)In the regimental service company:

- Bugler (Driver of 1/4 ton truck, Jeep)

- Messenger (Driver of 1/4 ton truck, Jeep)In the battalion headquarters:

- Bugler

- Orderly (Driver of 1/4 ton truck, Jeep)In the Rifle Company:

- Bugler

The M8:

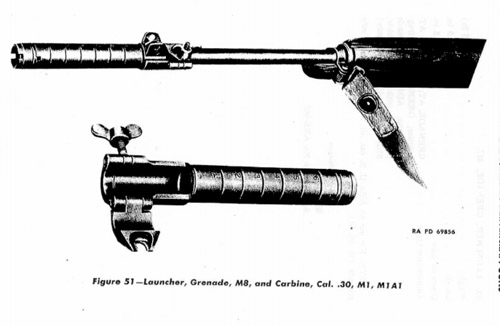

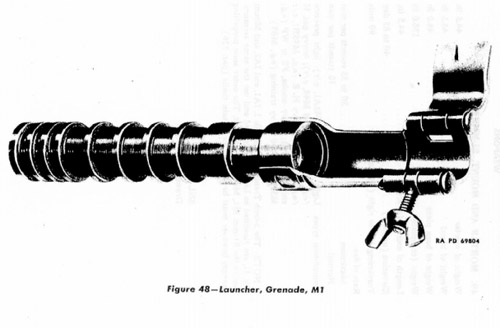

Photolink to CriticalPast Video of M8 grenade launcher Stateside Demonstration, January 1944Much like the M1 launcher for the M1903 Springfield, the M8 grenade launcher for the M1 carbine simply clamped onto the barrel around the front sight via a hinged door and wing nut. In a departure of design, to address lessons learned from the M1 launchers use of spring steel ranging clips the M7 and M8 launchers incorporated an integral spring to allow the user to position the rifle grenade at marked “range bands.”

M8 grenade launcher showing improved range bands

M1 Launcher showing grooves for range clips

Extracts from TM 9-2200 11 October 1943

A substantial number of changes were made to the M8 grenade launcher during the war, with three major variants being produced, each with multiple minor revisions. For our purposes, there are two major patterns, with most of us being familiar with the second pattern.

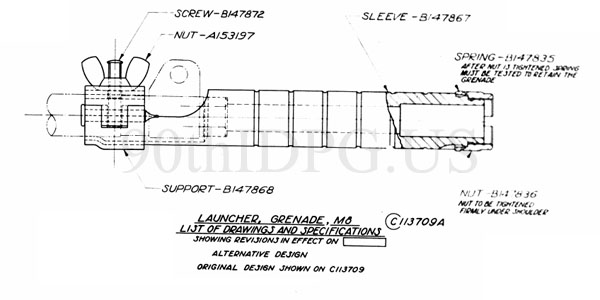

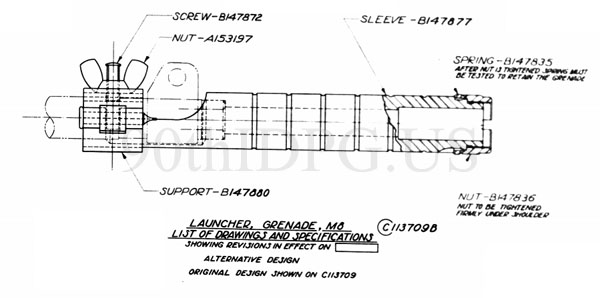

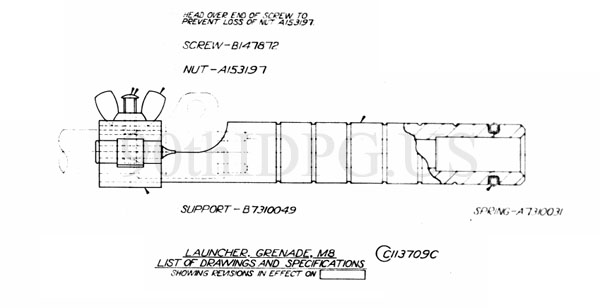

First Pattern – Nut & Split Ring type, Drawings C-113709A & C-113709B, all revisions.

Second Pattern – Coil Spring type, C-113709C, All Revisions

Design History:

The initial production drawing of the "Launcher, Grenade, M8," C-113709 A was drawn 5/23/43, this version being unique from others in the radiused rear of the bottom clamp assembly.

A simplified revision, C-113709 B, omitting the radius on the bottom clamp assembly was submitted on 6/23/43. The radius is entirely unnecessary for function, only serving a fractional weight reduction and cosmetic purpose. This simplification eliminates an unnecessary production task.

A final major version for the war, C-113709 C, replacing the split ring and nut with a coil extension spring was drawn 12/1/43. This was a major simplification and improvement for consistency. The split ring spring and nut each had to be individually adjusted and checked for the correct tension on a rifle grenade. Furthermore, the nut could and would loosen over time, requiring re-adjustment. Moving to a coil spring provided consistency of tension and eliminated all adjustment.

Additional revisions of the M8 grenade launcher were adopted post WW2, first replacing the solid wing nut with a stamped one, same as those seen on post war production flash hiders and muzzle breaks. The final revisions of the launcher inverted the clamp assembly to be standard with those produced for the muzzle break and flash hider, these each had inverted the clamp assembly so that the wing nut was on the bottom of the barrel and not in view of the front sight picture. These revisions are not illustrated as the focus of this article is on WW2 production and use.

Overall Production History:

There were two major production runs of the M8 grenade launcher during the war. The first production run was had purchase orders issued May 1943, with delivery beginning in August 1943 and completing in August 1944.

Sun Ray Photo Co. Inc. of New York City, Reliance Machine Tool Corp. of Long Island NY, and Knapp Monarch Co. of St Louis MO produced a combined 283,000 units during the first production run.

The second production run started in December 1944 and was terminated at wars end in August 1945. Knapp Monarch and U.S. Cabinet Bed Company of Brooklyn NY produced a further 104,000 units during the second production run.

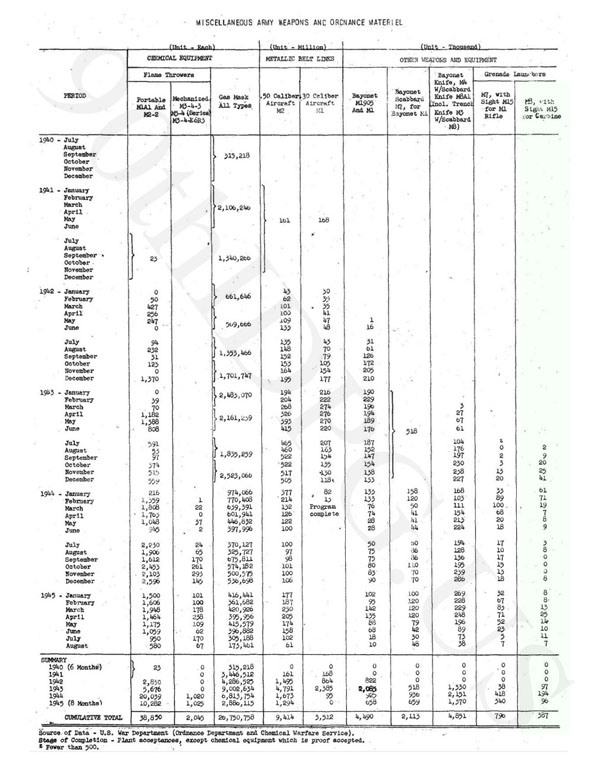

Conveniently, a history was published immediately after the conclusion of the war tabulating production of war material by month. The M8 grenade launcher is included in this summary, albeit it is a total across all manufacturers by month.

The question of how many launchers of what type is unanswered by the high level figures provided.

Chronology of M8 Grenade Launcher Revisions:

There are 2 major questions to answer:

1.) When did the switch happen from Nut to Spring?

2.) How many of each type were made?

First, looking for when did the switch happen from a design perspective-

Revisions A and B were finalized and carried further as of December 1943, with Revision C being the go forward design type.

Answer 1.) The switch from Nut to Spring happened December 1943.

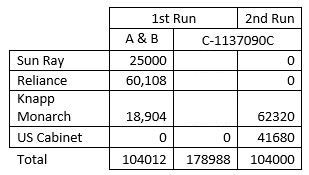

This chart captures revisions of each type, where minor details were changed, as well as showing when the switch from Nut to Spring took place, in context of each major production run.

Contract Chronology:

Now to answer the second question:

2.) How many of each type were made?

The contracts can provide us with the answer of how many were to be delivered, as well as in some instances, how many were actually delivered.

Reviewing the first Purchase Order updates 1944, after the drawing switch to Revision C gives us some clues.

1/21/1944 - Completion of Revision B, Switch to Revision C - Reliance Machine Tool

The 1/6/44 Reliance Machine line item has a contract revision pegging their contract at a maximum of 92,000 units, with the Government taking the right to re determine the contract downward if needed.

1/29/1944 - Mandatory Change Order - possible switch to Revision C - Sun Ray

The 1/21/44 Sun Ray line item shows the quantities to be delivered by Sun Ray broken out by price point, additionally their contract is noted to end Feb 44 - delivering their originally contracted amount of 25,000 units.

2/26/1944 - Price change due to redesign, delivery Jan - July - Knapp Monarch

The 2/22/44 Knapp Monarch line item shows a price change due to re-design, and a lowered quantity to be delivered, yet by the end of their contract, Knapp Monarch delivered 1000 units under their initial contract of 167,000 units.

After reviewing the contracts, my confidence in the exact numbers produced by maker wasn't high, specifically that it was unclear if Sun Ray made any coil spring Revision C units.

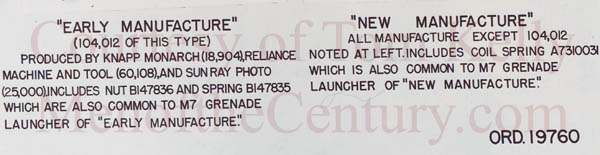

Going to another source, an original Ordnance Department image highlighting differences between the first and second pattern launchers also conveniently outlines the numbers by producer.

It states that 104,000 of the first pattern C-113709A and C-113709B launchers were produced. These figures are also cited by Bruce Canfield in "U.S. Infantry Weapons of WWII," who most likely used the same source.

This confirmed that Sun Ray only produced Nut type Revision A/B launchers, as well as establishing the production numbers for all the contractors.

Answer 2 A&B.) Knapp Monarch 18,904, Sun Ray - 25,000, Reliance Machine 60,108.

Production of the M8 grenade launcher ceased in August 1944, but the Ordnance Department saw a need for more at the end of 1944. The second run production began in 1945, with an initial contract being issued to Knapp Monarch in late December 1944 and a new contractor, US Cabinet Bed Co in January 1945.

12/20/44 - New Contract Award - Knapp Monarch

Knapp Monarch was back in production with a contract for 48,000 that was revised up.

1?/4/45 - New Contract Award - US Cabinet Bed Co

A new manufacturer, US Cabinet Bed Company of Brooklyn, NY was contracted for 38,000 - also seeing an upward revision prior to finishing their contract.

With the war's end in August of 1945, both manufacturers ceased production, with production figures listed below.

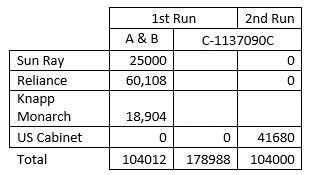

Algebra of Production:

Across the sources used in writing this article, no single source spelled out exactly the production numbers by manufacturer of each type. By combining the sources, we are able to solve for the table listed above - the editors felt it worth while to cite the sources and explain the math.

Here's what the table looked like before we calculated the values - just going off of the values clearly stated in the sources.

Both the primary sources and Canfield agree on the Early type at 104,000 produced. This fills in the values for the 1st column (A&B).

Both Canfield and the Munitions Production document agree on the Total number of M8 Launchers produced at 387K.

Canfield states in his Complete Guide to The M1 Garand and The M1 Carbine that US Cabinet delivered a total of 41,680 launchers. Based on data from Official Munitions Production of the United States, 104,000 launchers were delivered in the 2nd run. The math is 387,000 - 104,000 - 104,012 = 178,988 filling in the bottom row.

104,00 Total - 41,680 US Cabinet = 62,320 for Knapp Monarch. This fills in the values for the 3rd column (2nd Run).

Now to determine the breakdown of column two (1st Run, C-1137090C) by manufacturer-

Canfield states in his Complete Guide to The M1 Garand and The M1 Carbine that "All three firms produced M8 launchers at maximum capacity until February of 1944, when the requirements were reduced. Reliance and Sun Ray's contracts were not renewed after their original orders, but Knapp-Monarch maintained M8 production until July of 1944 when its initial contract was fulfilled."

As of January 22nd 1944, Reliance's contract was for 92K launchers total.

Now the Math to fill in First Run Revision C's.

Reliance Contract number 92,000 - 60,108 Revision A/B = 31,892 Revision C

Total 1st Run Revision C 178,988K - 31,892 Reliance Revision C = 147,096 KM Revision C

Photo Study:

In reviewing the photos on hand that illustrate usage of the M8 grenade launcher, the single theme that stands out to me is "Who was issued the M8" - within the Infantry Regiment we come back to Drivers, Messengers, Ammunition Bearers, Communications Sergeants, Reconnaissance Sergeants and Buglers.

Drivers:

Messengers:

Ammunition Bearers (Heavy Weapons Company - can tell because the blown up jeep was carrying 81mm Heavy M56/M57 ammunition tubes scattered about):

Communications Sergeant: (Note the TL29 and tape rolls)

Reconnaissance Sergeant:

Special Troops, Infantry and Armored all saw use of the M8 Launcher throughout North West Europe, from D-Day through the end of hostilities.

Summary and Conclusions:

The Army issued the grenade launcher to individual positions tasked with anti vehicle and tank defense - the launcher was just an accessory of the weapon carried. If the individual was issued a M1 Garand, they had a M7 launcher - if the individual was in a support role and issued a M1 carbine, they had a M8 launcher. The Tables of Organization and Equipment tell the story best. Having detailed the Infantry Regiment in this article, the Armored Regiment and other organizations have very similar data to reveal.

The M8 grenade launcher was produced and issued in significant quantities during WW2. As of Normandy, the launchers produced were split evenly between the early nut type and later coil spring type. Demand was sufficient to justify a further production run in late 1944 through 1945. Photographic evidence to further substantiate type issued in North West Europe is difficult due to quality, but the late coil spring type are conclusively observed.

This article should serve as a jumping off point for your own unit specific research, starting with your TO&E, photographs, G4 Supply records, memoirs and secondary sources. Many unit specific surprises exist, with deviations from the TO&E, such as Airborne use of the M8 Launcher in Normandy.

Sources:

Canfield, Bruce N. "The M1 Carbine Accessories and Accoutrements."Bruce Canfield's Complete Guide to the M1 Garand and the M1 Carbine. Lincoln, RI: Andrew Mowbray, 1999. 217-220. Print.

Canfield, Bruce N. "Grenades and Grenade Launchers." U.S. Infantry Weapons of World War II. Lincoln, RI: Andrew Mowbray Pub., 1994. 227-229. Print.

TM 9-2200 Small Arms, Light Field Mortars and 20-mm Aircraft Gun, United States. War Department, 11 October 1943, Print

Table of Organization and Equipment No. 7-11, Infantry Regiment (Dec 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015

Table of Organization and Equipment No. 7-12, Headquarters and Headquarters Company, Infantry Regiment (Feb 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015

Table of Organization and Equipment No. 7-13, Service Company, Infantry Regiment (Feb 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015

Table of Organization and Equipment No. 7-14, Infantry Cannon Company (Feb 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015Table of Organization and Equipment No. 7-15, Infantry Battalion (Feb 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015

Table of Organization and Equipment No. 7-16, Headquarters and Headquarters Company, Infantry Battalion (Feb 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015

Table of Organization and Equipment No. 7-17, Infantry Rifle Company (Feb 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015

Table of Organization and Equipment No. 7-18, Infantry Heavy Weapons Company (Feb 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015

Table of Organization and Equipment No. 7-19, Infantry Anti-Tank Company, 57mm Gun (Feb 26, 1944):MilitaryResearch.Org. War Department,Web. 30 May 2015

War Production Board. Official Munitions Production of the United States, By Months, July 1, 1940 through August 31, 1945. Civilian Production Administration, 1947. Print.

90th IDPG Articles