81mm Shell, M43

This article is from TM 9-1904 which is available on this site.

The contents have been supplemented with modern photos and comments or additional information added in some instances.

Date Compiled: 7/17/2007

Editor: Chris Guska

SHELL, H.E., M43. The shell was originally adapted as the light shell for the 81-mm mortar. It is designed for use against light targets such as machine gun nests, barbed wire entanglements and personnel in the open.

Shell body. The body of this shell is constructed of forged steel. It is tear-dropped in shape; that is, blunt nose and tapered tail. It has a bourrelet machined near the nose of the shell consisting of several annular grooves which serves to act as a forward bearing surface and a gas check. The action of the propelling charge gases expanding in the grooves and contracting to pass the raised portions tends to slow the gases and prevent their passing the bourrelet. The nose is machined and threaded to receive an adapter. The adapter is threaded and acts as a bushing for bakelite fuse well cup and the fuse. The bakelite fuse well cup is fitted to the adapter before it is assembled to the shell body and prevents the entrance of foreign material into the fuse cavity prior to the assembly of the fuse to the round. The fuse used is the Point-detonating Fuse M45. This fuse has a selective element and can be set for either super quick or delay action. (For details, see pages 295 to 298.) To the rear of the bourrelet is a curved taper reducing the base of the shell to approximately 1 1/Z inches. The base is closed and machined so as to receive a stabilizer assembly. The shell filler is 1.22 pounds of TNT. The total weight of completely assembled round is 7.05 pounds. Entire length of the fused shell is 13 1/4 inches.

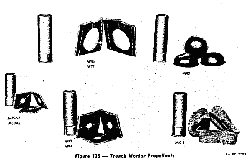

Fin assembly. The fin assembly consists of a machined cartridge container to which are attached six stationary fins. One end is closed and threaded so as to be screwed on to the body of the shell. The other end is machined and hollow inside so as to receive the ignition cartridge. Several holes leading from the interior to the exterior periphery of the cartridge container serve to conduct the flames from the ignition cartridge to the propellant increments which are seated in the fins.

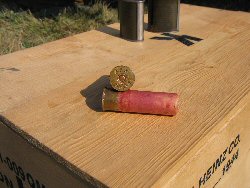

The Ignition Cartridge M3, red. is similar in appearance to a shotgun shell; the head is of brass and contains the percussion primer; the body is of cardboard, red in color, and contains 120 grains of finely granulate double base powder. It is designed to fit into the hollow portion of the stabilizer assembly.

The propellant increments are in the form of small half-round celluloid increments. These increments are often referred to as "chocolate drops" due to their similar shape. Each of these increments contains 100 grains of finely granulated double base powder. Note, in the figure below, the “chocolate drops” are labeled as M45.

A total of one ignition cartridge and a set of increments comprise the full propelling charge (720 grains of ballistite). The increments are held in the stabilizer assembly by small flanges on the fins and may be removed to adjust the propelling charge.

Zones of fire and range. This shell has seven zones of fire. The first zone of fire consists of the ignition cartridge. Zone seven consists of the ignition cartridge and six increments.

Zone one has a range of approximately 100 yards.

Zone seven has a range of approximately 3,300 yards.Marking and packing. The shell body is painted olive drab lusterless with yellow stencil to indicate H.E. filler. The stenciling includes the following information: caliber of weapon, kind of filler, model number of shell, and ammunition lot number.

For storage, shipment, and issue this shell is packed as a complete assembled round with the fuse and propelling charge in place.

It is packed one round per individual fiber container, six containers per bundle. Weight of a full bundle is 59 pounds. It may also be packed one per individual fiber container, eight containers per wooden box. Weight of a full box is 91 pounds.

Individual fiber containers are sealed with adhesive tape. The color of the tape and stenciling indicate the type of the shell inside.

Metal plates are placed on the ends of each packing bundle. One plate gives the number of rounds contained in the bundle, the nomenclature of the rounds, the lot number, and initials of the loading plant. The plate at the opposite end gives the proper shipping name as listed in SNL R-4, the total weight of the loaded bundle, and cubic displacement.

Packing bundles are held together by a rod passing through the center of the bundle with a wing nut at the end. After assembling, each bundle is sealed with a wire and lead seal. If this seal has not been broken, the bundle may be considered as the original package, positively identified by the metal plates at the ends of the bundle and by the marking of the fiber container.

90th IDPG Weapons