M3A4 Handcart Restoration Log - Part 3

Nuts, Bolts & Body WorkDate Written: 10/9/2010

Author: Chris Guska

Its been two and a half years since I did any real work on my handcart. A lot has happened since then. Unit member Steve has also acquired a handcart and we've been working on parallel restorations. His interest in the project has been the catalyst to putting things back in motion.

September 2010

Steve ordered parts from McMaster Carr, Ed Snyder and Hayes Otoupalek. His cart was missing all the nuts and bolts, the lunette, drawbar bracket and drawbar.

The nuts and bolts on the carts are fairly unique and there isnt an exact match off the shelf from any hardware supplier that we have found. There is a close commercial off the shelf replacement - which is what Steve ordered. I must note that there are some superb reproduction nuts and bolts available on the market that are absolutley correct.

The hardware that Steve chose to use on his cart is:

Part - McMaster Carr Part # - Price / Quantity as packaged

5/16 18 Nuts - 95036A016 - $8.06 per Pack of 25

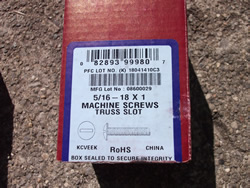

5/16 18 Truss head screws 1 inch - 90271A583 $5.59 per Pack of 25

5/16 18 Truss head screws 2 inch - 90271A591 $9.28 per pack of 25

5/16 SAE Washer - 90126A030 - $3.67 per Pack of 192The hardware as delivered from McMaster Carr was zinc plated. The plating was thin and unattractive. We took the time to media blast the hardware (plating FLAKED off when blasted) - then zinc phosphate the hardware.

My cart was missing the tow rope loops that are welded on the body, so I had to fabricate some. These are made from 5/16" round stock, heated with a torch then bent around a piece of pipe. It took a couple of tries to get just right, but I was pleased with the results in the end. I was fortunate to have Steve's cart in the shop so I could put my new ones right next to his originals and do an eyeball comparison till I got them right.

Both carts were missing 1 slat from the body. These were a bit of a cludge... If you have to have slats made and you dont have a very capable sheet metal shear and brake, take it to someone who does. The brake we had access to was not up to the job, which took some creativity to get these things done.

A special thanks to Craig Johnson for his help in drawings and some measurements for me.

Once the slats were fabricated, we spot welded them in place. I had access to a great 230V spot welder that usually will weld just about anything, but these slats were problematic and just did not want to stick. Not my first rodeo with a spot welder, but this was pretty special...

The photo above is of Steve's handcart body. One side of the slat on his body popped loose while we were at the shop, so we took the time to go back and make sure it was secure. I wasnt as lucky or thoughtful. As soon as I got home from the shop, one side on my cart popped loose.

The new front of the cart has been welded in from where I removed the panel that had been previously modified.

I went ahead and primed my cart body. I still need to reinstall the drawbar bracket as well as the spacer block for the main tube.

From this point, I need to do a bit of body work / spot filler on some badly pitted areas. After that I'll mount the riveted on hardware (drawbar bracket & spacer) - then basecoat everything in OD. Once basecoated in OD, I can begin final assembly and a final topcoat of OD.

M3A4 Handcart Restoration Log - Intro

M3A4 Handcart Restoration Log - Part 2

M3A4 Handcart Restoration Log - Part 4

90th IDPG Weapons