IMPORTANT:

Proceed at your own risk. We're not responsible for you blowing yourself or your gun up

Blank Adapting the M1917A1 Watercooled Machine Gun

Date Written: November 2011

Author: Chris Guska

Blank Adapting the M1917A1 Watercooled Machine Gun

1.) Selecting blanks

2.) Feedway modifications

3.) BFA Construction

4.) Gland Packing

5.) Belts vs Links

6.) Feed parts

7.) Troubleshooting (You are here)

1.) TroubleshootingTip #1 - Headspace

There's a lot of ways of setting headspace on Browning 30's. I use the breeching method - and it provides me with the best results. This youtube video covers it very well. I run @ 2 clicks out of Zero.

1919a4 headspace gages aren't necessary. They're a nice display item that you don't need to run the gun successfully.

Tip #2 - Timing

Timing only applies to full auto Browning 30's. This youtube video covers it very well.

Tip #3 - Topcover latches

The topcover may "pop open" when firing blanks. This is a symptom of 2 potential issues - 1) Too much pressure, aka aperture size too small, or 2) Worn topcover / latch interface.

Topcovers and latches are sometimes worn on kits. It happens. Latches are $10-15 and worth having a spare of. Topcovers were to be fitted to latches by filing a bevel on the top rear edge of the cover plate. As things got mixed around and used, often times that clearance has grown too large.

Tip #4 - Examine your brass / cartridges

This is a big one. With brass case blanks, if you have feed issues and notice that your bolt is taking a chunk/notch out of the cartridge case rim - you need to do a small modification to the bolt.

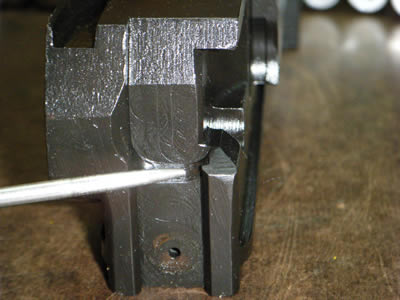

When looking at the front of the bolt, the face towards you - grind down the top right (feed in) of the T slot. There is a point there which can clip the rear of the round that needs beveled / cleaned up.

Plastic case blanks will present differently, as they do not have the case strength of brass cases. They will crush at the tip / nose rather than have any damage do the rim. DO the above modification to the bolt face.

If the issue still presents itself, take a couple of file passes off of the front feed guide.

Tip #5 - Lubrication

Many 1919 owners tout the virtues of running their guns sopping wet with various lubricants.

I don't believe in this. If a gun needs to be dripping wet to simply run - there is something wrong with it.

Less is more. A dab here and there of grease, and a little oil goes a long way in my opinion. The browning 30 gets pretty dirty, especially after a couple of thousand rounds. I've found that more lubricant just makes more dirt stick.

Tip #6 - Know when to douche.

I've found the magic number to be approximately 3000 rounds of blanks to be the stopping point for my browning 30's. I'll simply pull the major assemblies out and douche everything with a can of brake or carb cleaner. Wipe with a rag to get the rest off, lightly oil and reassemble.

Do this before you put the gun away for the night. Don't wait until the next morning.

Tip # 7 - Spares

Things to carry in the field with you in your M12 tool roll:

Flat head screw driver

Extra complete extractor assembly

Extra complete firing pin assembly

Extra feed lever

Extra feed lever pin

Extra sear

2x Extra topcover extractor springAllen wrench

Extra set screws / aperturesOval GI Oiler

90th IDPG Projects